The MAXIMATOR valves, fittings and tubing are suitable for different media and operating pressures up to 10,500 bar.

Based on decades of experience in the field of high pressure technology MAXIMATOR manufactures valves and fittings for the chemical industry, water-jet cutting, power systems and test bench manufacture.

A modern manufacturing operation has been established at our Nordhausen factory. The plant complies, especially in the high-pressure area, with all requirements to ultra-clean production and thus ensures highest fabrication and quality standards.

A modern manufacturing operation has been established at our Nordhausen factory. The plant complies, especially in the high-pressure area, with all requirements to ultra-clean production and thus ensures highest fabrication and quality standards.

The MAXIMATOR team is highly qualified and experienced in high-pressure technologies. Following final inspection the components are shrink wrapped which guarantee dust-free delivery to their destinations.

Continuous marking ensures proper traceability of all MAXIMATOR Valves and Fittings. Following product relevant datas are marked by a sophisticated laser device.

Prior to serial release MAXIMATOR high pressure valves of the 4,500 bar / 65,000 psi series are subjected to an extensive functional test at 5,000 bar / 72,500 psi.

A number of valves are simultaneously tested, as shown in the picture.

The tested valves are continuously actuated and thus facilitate different pressure loads.

Thus, the HP bodies, bolted unions and HP sealings are tested under pressure.

Also after very frequent opening and shutting, MAXIMATOR high pressure valves prove their tightness and smooth running.

These MAXIMATOR pulse test rigs are used to test MAXIMATOR high pressure valves at 4,000 bar / 58,000 psi and 10 Hz.

Thus, the permanent stress cycle strength of MAXIMATOR high pressure valves is proven, which is an integral element of the QA/QC system at MAXIMATOR.

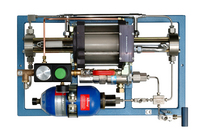

The MAXIMATOR high pressure program is put to a large variety of uses. Some components have been installed into a MAXIMATOR high pressure unit for a max. 5,500 bar / 79,000 psi.

Smooth running and a sturdy design ensure that MAXIMATOR high pressure valves are fully functionable also under the most adverse operating conditions.

This booster station compresses gases to 500 bar / 7,250 psi. Here, it is of utmost significance to employ reliable connecting elements.

The compressed gas is first led into a cross and then via a tee on to the accumulator.

The gas may be supplied to a consumer from the tee. It is also possible to use an additional valve to supply further consumers.