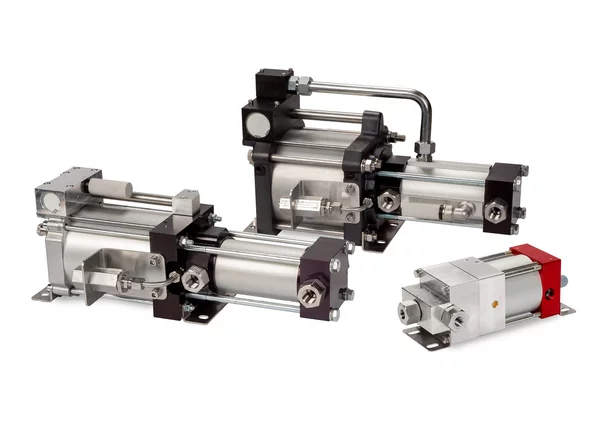

The Maximator LGP (Liquified Gas Pump) series was developed for use with refrigerants. The design of these pumps is based on the mode of operation of gas compressors in combination with proven high-pressure pump technology.

The technology has been optimized for the compression of liquid and gaseous fluids, so that the pumps of the LGP series can compress and convey both aggregate states.

Another special feature of this series is its suitability for the compression of flammable media. A flameproof enclosure according to DIN EN 60079-1 including a TÜV test has been implemented. Thus, the pumps of the LGP series can be used for a variety of fluids.

The SLGP and GLGP pumps are also optionally available with reduced stroke. On the one hand, this reduces the size of the pump and, on the other hand, this reduces the likelyhood of icing on the muffler. Should a phase transition nevertheless occur, the pumps of the Maximator LGP series can also pump the fluid in the gas phase without impairing functionality.

Common climate-friendly refrigerants are mostly flammable. Should a flammable mixture of the refrigerant and oxygen form inside the pump, ignition can occur. In the event of a leak on the high pressure side, a flammable gas mixture could form in the combined leakage hole that has a connection to the air drive. This can trigger an explosion in the event of ignition.

The resulting flame is stopped immediately in the flame arrester, which prevents the thermal energy from spreading. In addition, the space of the combined leakage line is designed and tested according to DIN EN 60079-1, so that no flame can escape. There is a flameproof enclosure in accordance with gas group IIB.

The pumps may be operated in potentially explosive atmospheres with appropriate precautions.

|

|

Phase transitionsEasy handling of occurring phase transitions |

|

|

Increase availabilityFluid-resistant material selection |

|

|

Application orientationApplication-optimized technology to avoid icing or phase transitions |

|

|

EX-ZoneDesign of the technology for safe operation in EX zones |

|

|

SafetyFlame arrester and flameproof enclosure for the use of flammable fluids |