Pressure Vessel Test Service

Maximator offers you all legally required tests for pressure vessels as a service, such as Tests in accordance with ECE R110, ECE R134, EC79 / 2009 or EU406 / 2010 or even UN GTR no. 13. In addition, we can also offer services according to your individual requirements.

In our test laboratories, we assume responsibility to support your production tests of prototypes as well as to perform the quality control of serial parts.

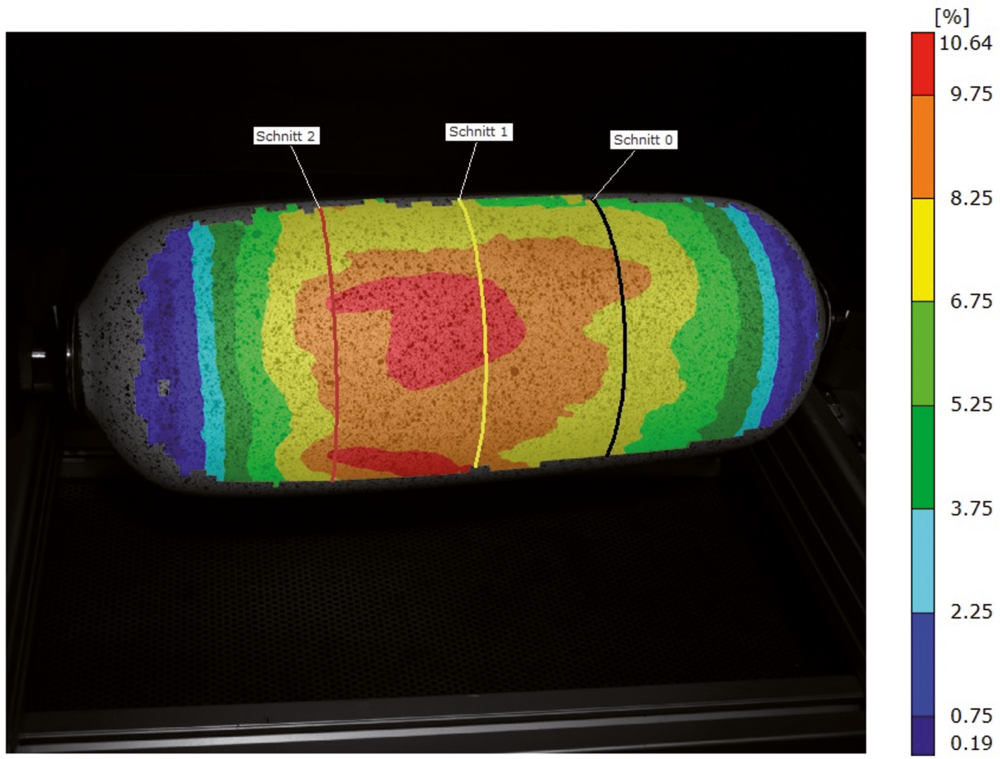

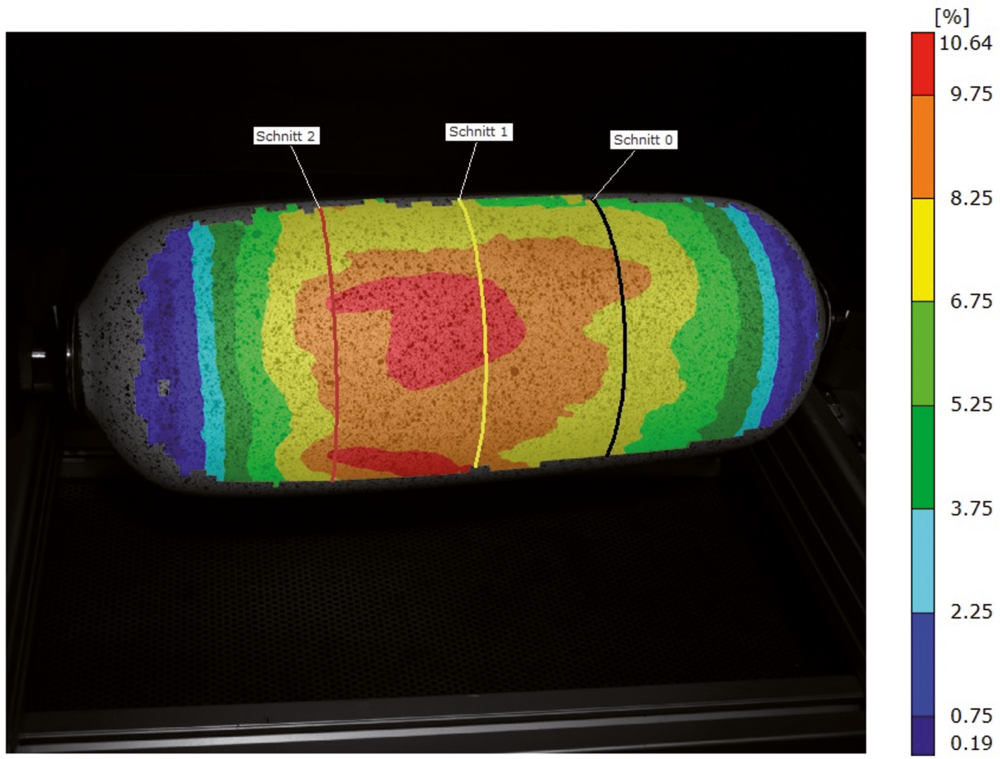

The MAXIMATOR service testing center not only carries out its own development activities, but also a wide range of tests as a service. (e.g. tests on large-volume composite components up to 500 litres capacity and 4 m long) It is possible, while testing a tank, to record its expansion behaviour in longitudinal and circumferential direction to accuracies of 0.1 mm using laser-optical expansion measurement. In the case of burst tests, tank failures can be recorded with the use of high-speed cameras to help determine failure modes. In addition, the new test stand in the Nordhausen service centre enables composite tanks to be placed under mechanical load (torsion and bending) in burst or pressure load change tests. This gives rise to informative insights into the burst behaviour of test specimens, which is advantageous to component assessment and helps to reduce development times.

Our service program:

- Proof pressure / Burst pressure tests

- Pressure cycle tests

- At ambient temperatures

- At extreme temperatures

- With pre-treatment (e.g. thermal, flaw, drop, crash)

- Leakage tests

- Real-gas cycles (e.g. with hydrogen)

- Bonfire and penetration tests

High-performance test equipment:

Burst pressure tests

- Pressure: up to 4,000 bar

- Volume: up to 500 l

- Length: up to 4,000 mm

- Variable pressure increase rates

Pressure cycle tests

- Pressure: up to 1,400 bar upper pressure level

- Frequency: up to 10 pressure cycles / min

- Ambient and fluid temperature: ≤ - 40°C up to ≥ + 85°C

- Reproducible sinus curve

Leakage tests

- Pressure: up to 1,050 bar

- Tracer gas: helium or hydrogen

- Integral test procedure under vacuum

- Local test procedure with a sniffer probe

- Traceable leakage rate up to 10-8 mbar * l * s-1

Real-gas cycles

- Pressure: up to 1,050 bar

- Volume: up to 150 l (6 kg H2)

- Length: up to 2,500 mm

- Diameter: up to 600 mm

- Ambient temperature: ≤ -60°C up to ≥ +120°C

- Fluid temperature: ≤ -60 °C up to ≥ +60°C

- Failure of the specimen under gas pressure accepted

Optional supplementary components:

- High speed recording of the burst process up to 10.000 images / second

- Laser-optical 3D deformation measuring

- Torsional moment up to 10,000 Nm

- Bending strength up to 15,000 N

Convincing benefits:

- Long-term experience and competence in high-pressure and test technologies

- Support of new developments

- Ensuring test reproducibility

- Performance of tests on short notice

- Shortening of product development cycles

- Cost-efficient solutions for your testing needs

- If required: Transfer to test stand technology